Quartz stone production process

Process flow of quartz stone production

I. raw materials

1, ingredients:

According to the required varieties of production, the preparation of all kinds of raw materials (quartz sand, resin, even mixture, curing agent, glass (Bai Bo, mirror glass), toner, titanium dioxide, according to the proportion of formula deployment.

The dosage of nano curing agent is 0.8-1.0% of resin dosage.

2, mixing: first, the proportion of good resin, and even mixture, curing agent and pigment mixed in a special mixing barrel for 2 minutes of mixing. At the same time will be called a small amount of quartz sand, glass poured into the automatic blender, add a good mixing of resin, curing agent and pigment, by mixing with Jun evenly, use when about 7 minutes.

3, mold bottom paper: the bottom of the prepared mold, laying a layer of kraft paper of the same specifications, the role is to cure, after the quartz stone and the mold between easy separation. We are currently the largest template specifications is 1.65 meters long by 3.25 meters wide, the template also put on the 4 sides of the medial rubber strip, rubber strip to height is 5MM higher than the mold plate. Lay a board, 3 people operate, use about 2 minutes or so.

4, the distribution of cloth: good raw materials are evenly distributed on the artificial template, make it as smooth and flat surface after basic, then cover it with a layer of kraft paper pad to a layer of rubber. The role is to avoid the pressure head press the suction plate. A long, 1.65 meters wide, 3.25 meters, a large plate of 1650*3250*12, need about 250 kilograms of raw materials, if 3 people operate cloth, about 4~5 minutes.

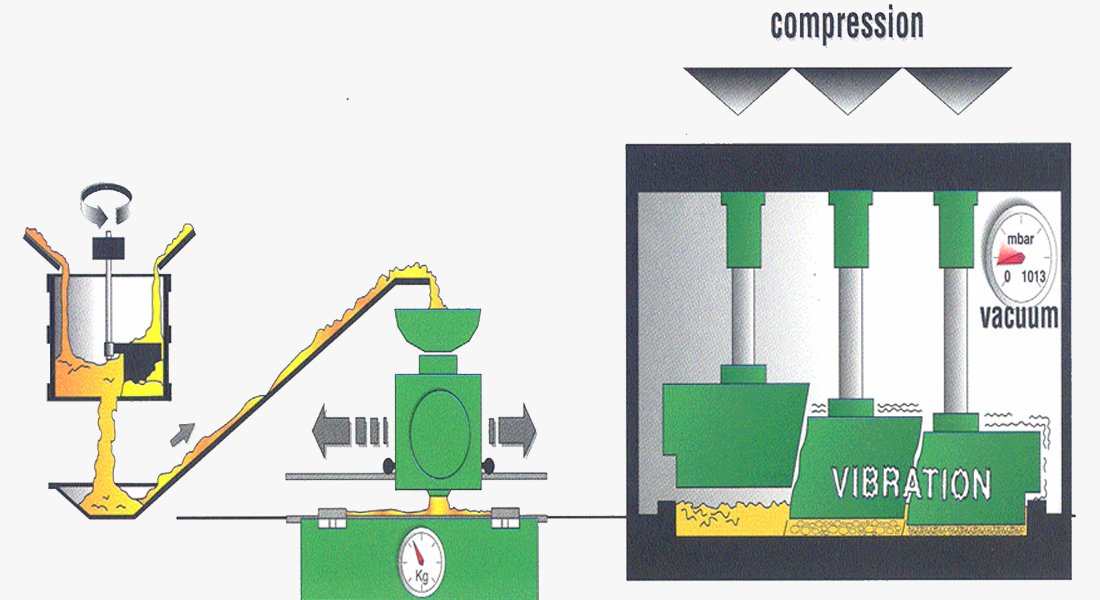

Two: forming

5, suppress:

After the cloth is finished, it is sent to the press by the automatic production line, and the vacuum operation is carried out for about 120 seconds. After the completion, the two pressurizing vacuum is carried out, and the two pressing time is usually about 25 seconds. Then vibration, pressure, vibration, pressure about time

About 200 seconds. Of course, the vacuum and compression time will vary according to the specifications and thickness of the sheet.

6, heat curing: after the finish of the quartz by vacuum pressure, automatic production line is transferred to the heat curing frame, heat curing, the curing time usually takes 40~60 minutes, curing temperature at about 80~90 degrees,

7, release: according to the prescribed time and temperature for heat curing, after the automatic production line to the release machine for demoulding.

Three: polishing, cutting

Problems often encountered in quartzite:

1 cracking

1.1, the amount of curing agent is too large, the resin gel time is very fast, a lot of heat will soon release, resulting in cracking.

1.2 curing, the temperature of the building is too high, causing cracking.

1.3, because of the large amount of filler, resin gel time is too slow, resin and filler can not have a certain adhesion in a short time, resulting in cracking.

1.4 the heat of the resin itself is too large. The heat release peak is too high at 80.

1.5, the toughness of the resin is relatively small, hardness is too large, but the strength is too high, shrinkage, resulting in excellent products,

1.6, in the production process, the cloth is not very uniform, part of the local mass of materials, part of the local mass less, contraction of different cracks.

1.7 in the process of pressing, the applied pressure is uneven, and it also causes cracking.

2 deformation

2.1 resin itself reasons, the strength is not enough.

2.2 because the curing is incomplete. The curing time of the resin can be increased, or the dosage of the curing agent, the curing temperature of the curing agent and the type of the curing agent can be improved.

2.3 press the pressure is not enough, resulting in deformation.